Cartridge Bullet Cups for Military Project

Military industry: Copper-steel composite material temperature and pressure-penetration composite technology is a new te

Basic Info.

| Model NO. | H90/F11/F18/H90 |

| Transport Package | Wood Pallet |

| Specification | brass / steel |

| Trademark | Estar |

| Origin | Ningbo |

| HS Code | 721260000 |

| Production Capacity | 10000tons/Years |

Product Description

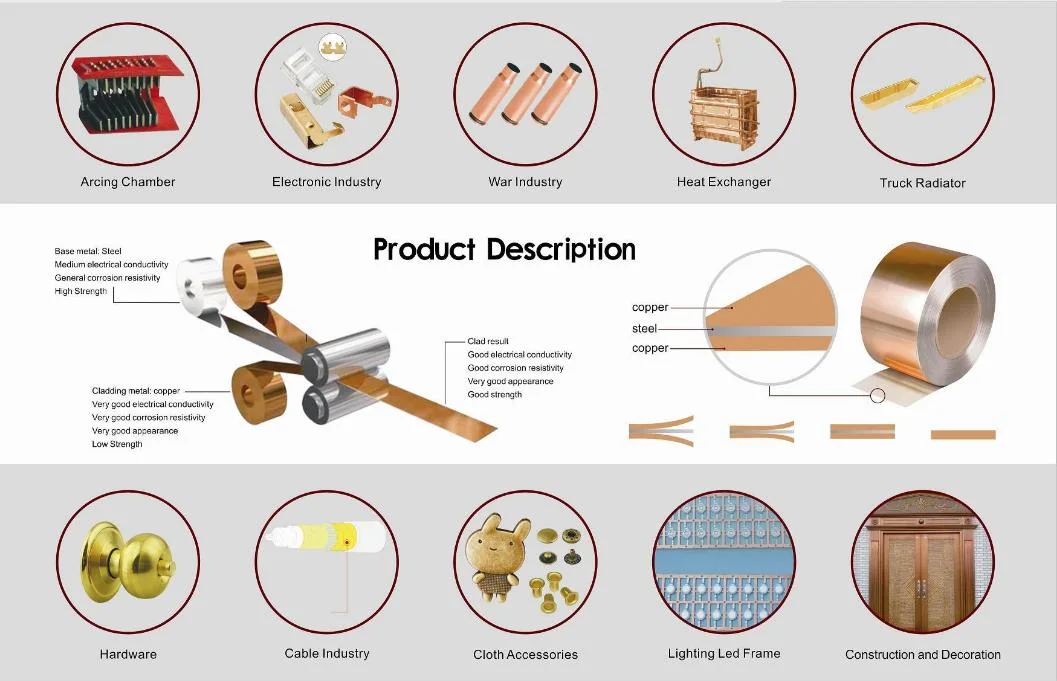

Military industry: Copper-steel composite material temperature and pressure-penetration composite technology is a new technology emerging in the field of domestic metal composite strip materials, in addition to the high strength, good heat resistance, thermal stability, plasticity and corrosion resistance common to composite materials In addition to the characteristics of resistance and abrasion resistance, in the field of military bullet manufacturing, there are also the advantages of high yield and high dimensional accuracy, which are beneficial to improve the quality of bullets; the composite material has good consistency, thereby ensuring the consistency of the bullet and the shell; One batch is heavy and can be processed continuously, which greatly improves the production efficiency of bullets. The surface quality is excellent, comparable to pure copper; the brass on the surface of the copper-steel composite material also has a lubricating effect, which can reduce the impact on the barrel when shooting The wear and tear of the barrel and rim. It has been widely used in military products such as bullet shells and detonators. The sales network of military copper-steel composite materials has covered the world and won unanimous praise from many customers.

This kind of product is formed by stamping the material of warhead shell, and it is also the first process of making bullet case. It can be customized according to the drawings provided by customers. The product materials include copper, composite copper, etc,

Chemical Composition

Grade | Chemical composition of steel strip | ||||||||

C | Si | Mn | P | S | Ni | Cr | Cu | Als | |

% | % | % | % | % | % | % | % | % | |

F11 | ≤0.11 | ≤0.06 | 0.30-0.55 | ≤0.02 | ≤0.01 | ≤0.3 | ≤0.15 | ≤0.2 | 0.02-0.1 |

F18 | 0.11-0.19 | ≤0.06 | 0.35-0.55 | ≤0.02 | ≤0.01 | ≤0.3 | ≤0.15 | ≤0.2 | 0.02-0.1 |

SPHC | ≤0.15 | ≤0.05 | ≤0.6 | ≤0.035 | ≤0.035 | - | - | - | ≥0.010 |

Grade | Chemical composition of copper strip | |||||||||

Cu+Ag (min) | P | Bi | Sb | As | Fe | Pb | S | Zn | Total impurities | |

% | % | % | % | % | % | % | % | % | % | |

H90 | 88-91 | - | - | - | - | ≤0.1 | ≤0.02 | - | allowance | ≤0.2 |